Looking for an easier method to rinse your 3D-printed parts? Inslogic Water-Washable Resin simplifies post-processing, making it quick and convenient without the use of isopropyl alcohol (IPA). Generally, washing methods can be categorized into three main types: cleaning with IPA or ethanol, using resin detergent, or just water. In this article, we will mainly explore the pros and cons of the water-wash method and provide a step-by-step guide to post-processing water-washable resin prints.

What Is Water-Washable Resin?

Water-washable resin is a type of 3D printing material that dissolves in water. Unlike traditional resins, which require cleaning solutions like IPA or resin detergents, water-washable resin can be cleaned with just water. When handling chemicals like alcohol, it's crucial to prioritize safety, as alcohol is flammable and can be harmful to the skin. Therefore, water-washable resin is a great alternative to consider.

You can bathe water-washable resin printed parts in tap water to clean off excess resin. For many resin printing enthusiasts, this simplifies their post-processing setup and saves money, as they don't need to buy additional cleaning supplies. Additionally, post-processing becomes easier and faster due to its straightforward nature. If water-washable resins meet your needs, they are definitely worth trying.

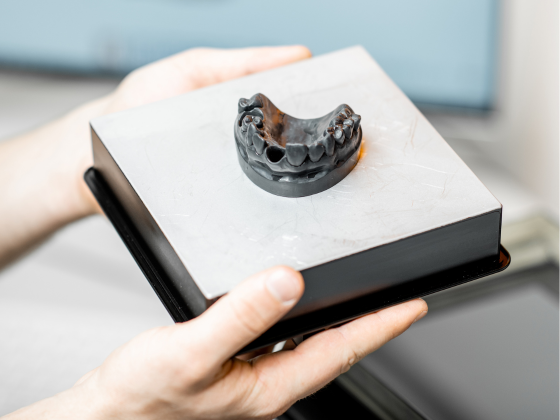

Water-washable resin is ideal for a variety of 3D printing applications, including miniatures, figurines, and prototype parts. Inslogic Water-Washable ABS-Like Resin delivers high resolution and produces prints with excellent hardness and toughness. Its strong and resilient properties make it a versatile choice for most 3D printing needs.

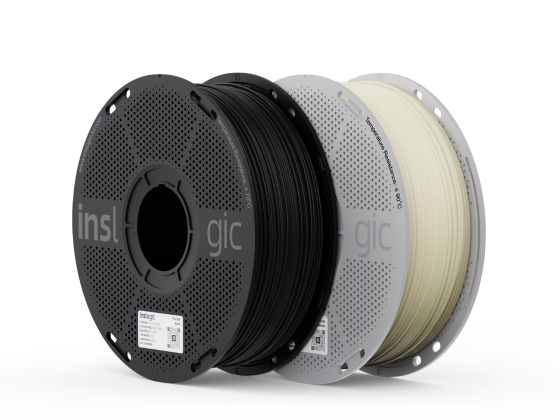

The Inslogic water-washable resin collection comes in four colors: grey, dark grey, black, and white. These colors highlight the intricate details of your prints and are incredibly easy to clean with just water.

Advantages of Water-Washable Resin

Water-washable resin offers several notable benefits, particularly in the simplicity of cleaning printed parts. Instead of needing other solvents, you can easily rinse the parts using an ultrasonic cleaner or just a simple bucket of tap water. This approach not only saves time but also enhances convenience.

Furthermore, water-washable resins emit less odor than traditional resins and provide a safer alternative to using IPA. Since IPA concentrations of 90% or greater are typically required, it is flammable and emits strong odor, so it must be handled with care.

Pros:

- Easy cleanup: Can be rinsed with water, eliminating the need for other solvents.

- Time-saving: Quick and straightforward cleaning process.

- Cost-effective: Reduces the need for additional cleaning solutions.

- Less odor: Emits significantly less odor compared to traditional resins.

- Safer use: Avoids the hazards associated with flammable and strong-smelling isopropyl alcohol (IPA).

- More environmentally friendly: Requires fewer chemicals and produces less odor.

Disadvantages of Water-Washable Resin

While the ease of cleaning is a benefit, be cautious with intricate models, as overcleaning can accidentally remove fine details from your prints.

Water-washable resin printed parts may turn out slightly more brittle than traditional resin. The main reason is that water-washable resin is soluble in water. The printed parts should be fully cured and kept away from water. Keep in mind that printed parts should not be left in water for too long; following the suggested procedure is recommended.

Additionally, to be a responsible printer, it is essential to avoid disposing of water containing uncured resin down the drain, as this can cause environmental harm.

Cons:

- Water-soluble: Overcleaning intricate models may wash away some fine details.

- Potential brittleness: Water-washable resin requires proper cleaning and curing to achieve the desired end properties.

- Environmental impact: Improper disposal of water with uncured resin can harm the environment.

How To Clean Water-Washable Printed Parts Properly

Water-washable resin printed parts can be conveniently cleaned with water. An ultrasonic cleaner is highly effective at removing contaminants when optimal chemistry, cleaning cycle time, and temperature are used. Alternatively, you can wash the printed parts in a bucket of tap water, using a brush to reach details like nooks and crannies.

Steps to Cleaning and Post-Curing Water-Washable Resin

Wash Procedure

- Step 1: Prepare two clean buckets with water. If necessary, use resin detergent or a low concentration of IPA.

- Step 2: Perform the initial wash for 1-3 minutes. For hollow models, agitate the model back and forth in the water to ensure the inner surfaces are cleaned.

- Step 3: Conduct a second rinse for 1-3 minutes. Thoroughly wash the surface and agitate the model to ensure all inner surfaces are properly cleaned. The total suggested wash time is around 5 minutes. For larger or intricate models, extend the washing time.

- Step 4: Final rinse for 3 minutes in ultrasonic cleaner.

- Step 5: Dry the model surface and inner parts with a high-pressure air gun.

Safety Reminder

Even though the resin is water-washable, using proper safety equipment is essential. Always wear gloves and a mask, and if working with resin for extended periods, consider using a respirator. Never touch the resin with bare hands, and if contact occurs, wash thoroughly with plenty of water immediately. For more detailed information, please refer to the Safety Data Sheet (SDS).

How to Properly Post-Cure Water-Washable Printed Parts

Post-curing enables parts to reach their highest possible strength and become more stable. It is highly recommended to use a UV curing station to cure the models. It is suggested to cure small models for 5-10 minutes and larger models for 20-30 minutes.

Store cured models in a dry environment, away from direct sunlight, for 60-90 minutes. Ensure the inner parts of the model are completely dry.

Disposal Guidelines

When it comes to solvent disposal, it is crucial NOT to pour residual water containing resin down the drain, as it can harm the environment. Always collect and properly dispose of used water to minimize environmental impact. One effective method is to place the water in the sun for a few days, allowing the resin to fully cure. Once cured, the resin can be safely discarded. You can then reuse the water for cleaning your next batch of water-washable resins or leave it in the sun until it completely evaporates.